Solar Ground System Maintenance Guide

Regular structural inspection and reinforcement

Bracket stability testing

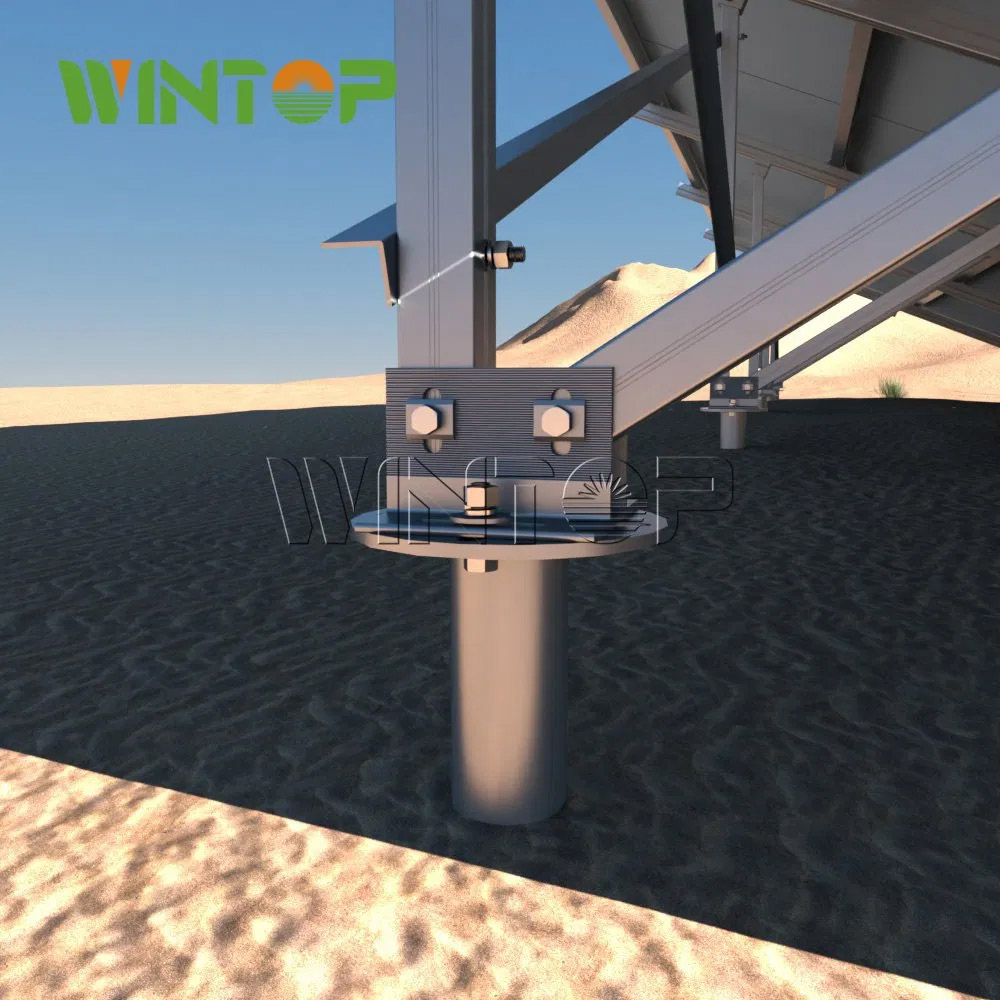

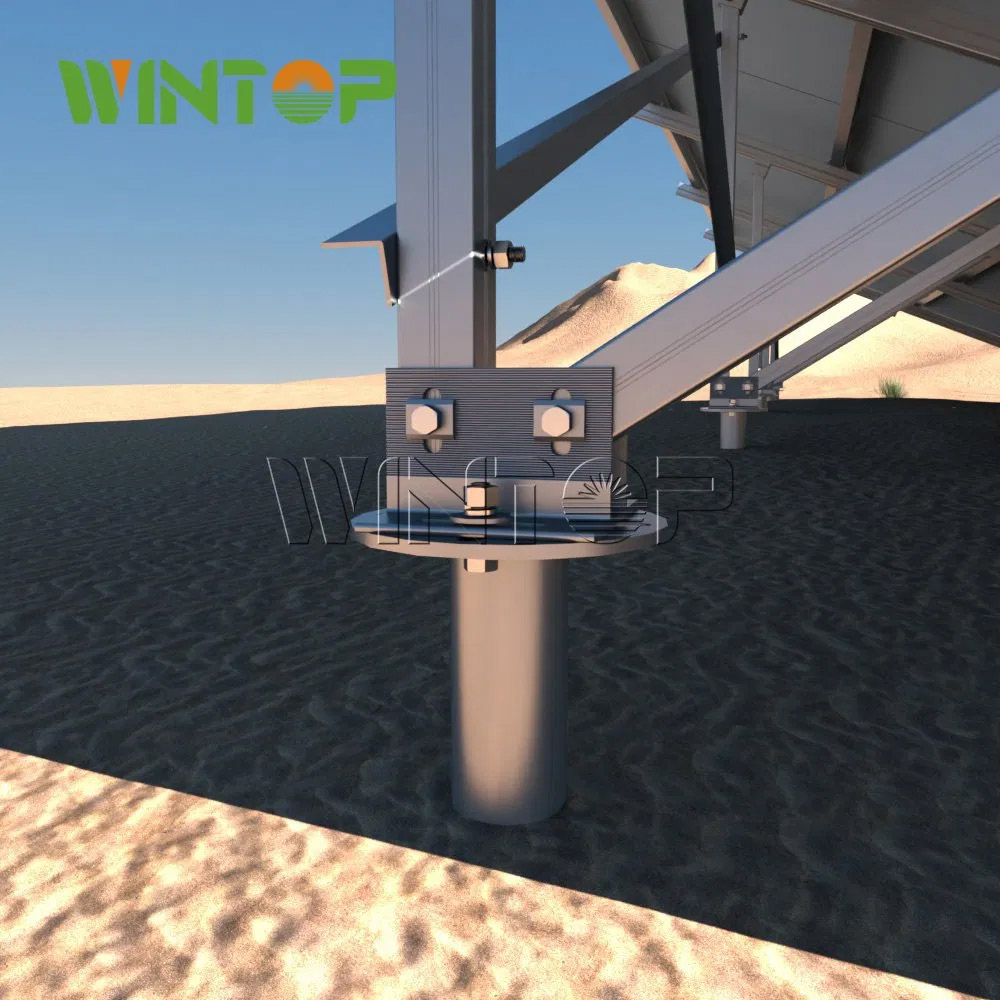

Check the steel bracket connection bolts for looseness every quarter, with a focus on inspecting the fasteners of the main beams and columns. If looseness is found, it should be repaired immediately and re tightened;

Ground supports need to be monitored for foundation settlement, and immediate correction is required when cracks appear in concrete foundations or when the displacement of spiral piles exceeds 5mm.

Anti corrosion and anti rust treatment

Check the wear of the galvanized layer on the surface of the steel bracket every 2 years. If there is rust, it needs to be polished and repainted with epoxy zinc rich primer and polyurethane topcoat, with a thickness of ≥ 120 μ m;

It is recommended to increase the maintenance of anti-corrosion coatings once a year in coastal/high salt alkali areas.

Cleaning and anti fouling management

Cleaning and anti fouling management

Component surface cleaning

Clean the photovoltaic panels every 15 days during non rainy seasons, and reduce it to once a week in desert/high dust areas to avoid using hard tools to scratch the glass surface;

The cleaning time should be before sunrise or after sunset, and the temperature difference between the water temperature and the components should be ≤ 15 ℃.

Drainage and anti siltation measures

Before the rainy season, check if the bracket drainage channel is blocked to ensure that the accumulated water is quickly drained;

The inclined bracket needs to be adjusted with an inclination angle of ≥ 30 ° to use rainwater self-cleaning to reduce dust accumulation rate.

Extreme weather response plan

Extreme weather response plan

Typhoon/Strong Wind Protection

After typhoon warning, it is necessary to comprehensively check the connection points of the support wind resistant cables and stay rods to ensure that the wind load capacity is ≥ 1.3 times the local maximum wind speed;

The burial depth of the ground spiral pile foundation should be ≥ 2.5m, and it is recommended to add counterweights in desert areas.

Lightning protection

Before the thunderstorm season every year, the lightning protection grounding resistance should be tested, with a requirement of ≤ 4 Ω. If it does not meet the requirements, a grounding electrode should be installed;

Prioritize disconnecting the circuit breaker of the combiner box during maintenance to avoid the risk of live operation.

Intelligent monitoring and fault response

Intelligent monitoring and fault response

Data based operation and maintenance

Deploy IoT sensors to monitor the stress and deformation of the bracket in real-time, and trigger an alarm when the offset exceeds 3 ‰;

Reverse troubleshooting of support structure issues based on abnormal fluctuations in power generation data (such as a daily decrease of ≥ 15%).

Fault classification processing

Level 1 malfunction (such as bracket fracture): on-site repair and activation of redundant support are required within 4 hours;

Secondary faults (such as loose bolts): Closed loop treatment and updated maintenance records within 48 hours.

Safety operation standards

Safety operation standards

It is forbidden to change the support structure or remove the diagonal brace without authorization, and the hydraulic system maintenance shall be operated with a certificate;

High altitude operations require the use of anti fall devices, and the tool kit should have a magnetic anti fall design.

Through systematic maintenance, the lifespan of the bracket can be extended to over 25 years, reducing the average annual maintenance cost by 30% -40%.