Wearable Solar Cells

Solar-powered wearable technology is through the integration of USB connections or other devices, which allows connecting from clothing to devices such as sources, phones and earbuds, which can be charged on the go.

Just a few years ago, a group of Japanese researchers at the Riken Institute and Torah Industries described the development of a thin organic solar cell that would heat-imprint clothing onto clothing, allowing the cell to absorb solar energy and use it as a power source.A micro solar cell is an organic photovoltaic cell with thermal stability and flexibility up to 120°C.Members of the research team based organic photovoltaic cells on a material called PNTz4T. PNTz4T is a semiconducting polymer previously developed by Riken for excellent environmental stability and high power conversion efficiency, and then both sides of the cell are covered with elastomer, a rubber-like material. In the process, they used two pre-stretched 500-micron-thick acrylic elastomers that allow light to enter the cell but prevent water and air from entering the cell. The elastomer used helps reduce degradation of the battery itself and make it last longer.

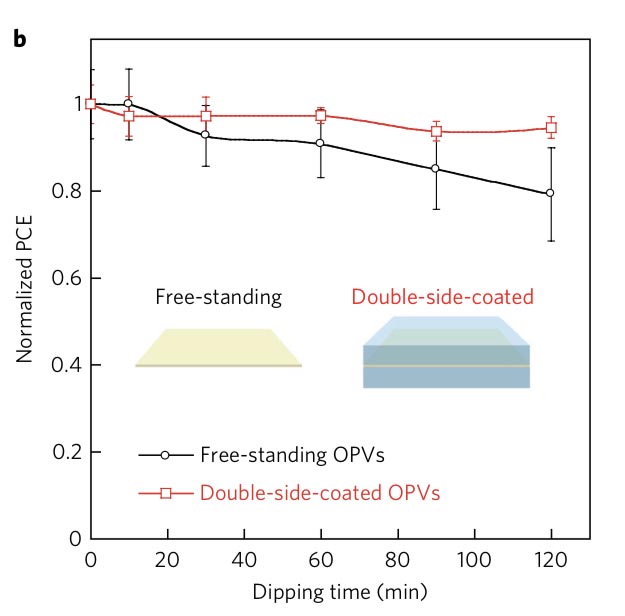

One of the industry's most notable drawbacks is water. The degeneration of these cells can be caused by a variety of factors, but the biggest is water, the common enemy of any technology. Any excess moisture and prolonged exposure to air can negatively affect the efficiency of organic photovoltaic cells. While you can avoid getting water on your computer or phone in most cases, you can't avoid it with your clothes. Whether it's rain or a washing machine, water is inevitable. After various tests on the free-standing organic photovoltaic cell and the double-sided coated organic photovoltaic cell, in Figure 1, both organic photovoltaic cells were immersed in water for 120 minutes, it was concluded that the power of the free-standing organic photovoltaic cell was The conversion efficiency was reduced by only 5.4% and the cells were reduced by 20.8%.

Figure 1. Normalized power conversion efficiency as a function of immersion time. Error bars on the graph represent the standard deviation normalized by the mean of the initial power conversion efficiencies in each structure

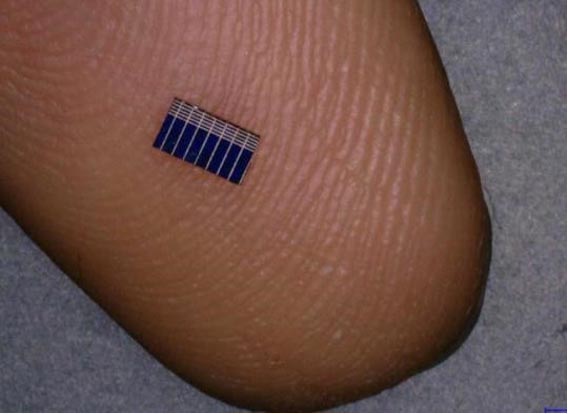

Figure 2 depicts another development at Nottingham Trent University, a miniature solar cell that can be embedded in yarn, which is then woven into textiles. Each battery included in the product meets specific standards for use, such as the requirements of 3mm long and 1.5mm wide. Each unit is laminated with a waterproof resin for laundry in the laundry room or due to weather. The batteries are also tailored for comfort, and each is mounted in a way that does not protrude or irritate the wearer's skin. In further research, it was found that in a small piece of clothing similar to 5cm² of fabric, one cell could contain just over 200 cells, producing 2 under ideal conditions.

Figure 2. Tiny solar cell measuring 3 mm long and 1.5 mm wide

Photovoltaic fabrics fuse two lightweight and low-cost polymers to create energy-generating textiles. The first of the two components is a tiny solar cell, which harvests energy from sunlight, and the second consists of a nanogenerator, which converts mechanical energy into electricity. The photovoltaic portion of the fabric consists of polymer fibers, which are then coated with layers of manganese, zinc oxide (a photovoltaic material), and copper iodide (for charge collection). The cells are then woven together with a tiny copper wire and integrated into the garment.

Categories

New Blog

© Copyright: 2026 Xiamen Wintop New Energy Tech Co., Ltd.. All Rights Reserved.

IPv6 network supported

Friendly Links:

Integrated Solar System